In this section you can navigate through our products and quote those that are your interest |

Products

Fluxes and Chemicals

|

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

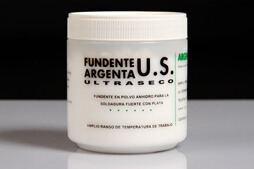

Silver Brazing Flux (Low Temperature)ARGENTA "U"Fundente Universal para la Soldadura Fuerte con plata. Description ARGENTA "U" is a white paste flux of creamy consistency and wide protective range up to 980ºC. This flux has been designed for the majority of the Brazing operations, specially for Copper-Copper joints and Copper, Steel, Stainless Steel, Nickel, Carbide base alloys, and also precious metals and heat resistant alloys. ARGENTA "U" is better used in spray, or other methods or automatic applications. This flux neither gets hard nor crystallized, maintaining its creamy texture for over two years. Aplications ARGENTA "U", is widely used in industrial applications, such as: automobile appliances, carbide tools, agricultural machinery, heat interchangers, power equipment, mining tools, musical instruments, refrigeration and air conditioning, naval ship reparation, air industry, etc. Physical Properties

Instructions ARGENTA "U", can be used in its original concentrated version, or dilute in water destillationed for thining its consistency. ARGENTA "U" gets less viscose when it's heated between 60ºC and 82ºC, increasing its activity. During the brazing process, heat up the flux softly avoiding spattering and bubbling excess. The residuary flux is hot water soluble, needing no brushing or sanding. Safety Precautions ARGENTA "U", is a chemical product containing double salts of the hydrofluoric acid. As such, it must be handled with care. Avoid contact with skin, eyes, and clothes. Wear eye protection, rubber gloves, and appropriate clothing. As additional precaution you must wash your hands after use. Brazing must be effected with proper ventilation. |

|||||||||||||||